Beijing International

Beijing International

Beijing, China

March 26-28,2026

Huatong petroleum, as a wholly-owned subsidiary of public listed company Huatong group (605196.SH), is an intelligent oil and gas solution provider of R&D, Production, Sales and Service. Through global strategic layout, It has a global marketing and service network, with production bases in many countries including Kazakhstan, Tanzania, Cameroon, Kazakhstan, Korea, Angola and Panama, as well as warehouse or subsidiary in the United States, Singapore and Hong Kong, and our business scope covers more than 100 countries and regions in six continents.

Huatong implements international mainstream standards strictly and has established a quality management system conforming to international standards. It has passed certifications including the API Spec 5ST, API Spec Q1, ISO9001, ISO14001 and ISO45001. The coiled tubing meets the requirements of API Spec 5ST after being inspected by CNPC Tubular Goods Research Institute (TGRI).

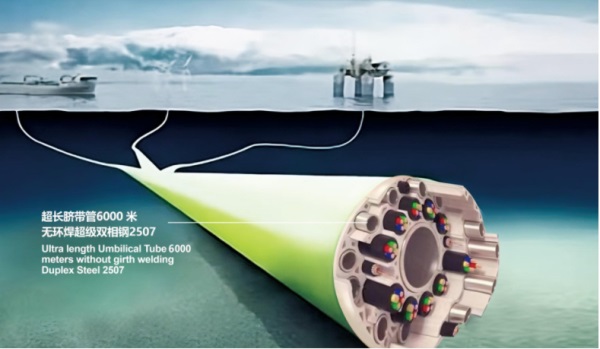

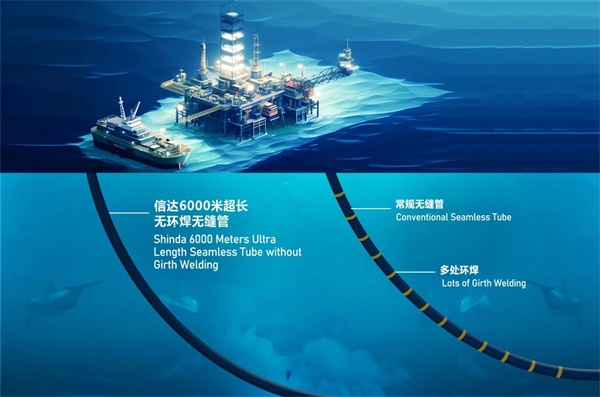

Shinda Ultra length Umbilical Tube 3000 meters without girth welding

Super Deplex 2507 Seamless Tube design (IP 71202220093537.7) effectively solve conventional seamless tube potential welding internal burrs and groove corrosion, avoid welding defects like partial welding and lack of weld.

Shinda patent Heat Treatment Process efficiently control duplex steel detrimental intermetallic phase , dramatically increase local corrosion resistance, withstand the harshest environments like HT/HP and High H2S/CO2.

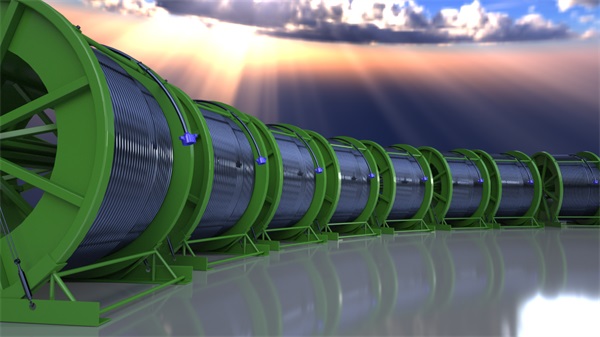

We develop patent (IP 71202220093537.7)production line for Ultra Length Umbilical tube for 3000 meter without girth welding.

Shinda 3000 meters ultra length seamless tube without girth welding

A solution to withstand offshore unforgiving challenges like high temperatures, high pressures and extreme corrosion, we customize engineering Hi-tech (IP 71202220093537.7) Shinda 3000 meters ultra length seamless tube without girth welding, effectively solve conventional seamless tube potential welding internal burrs and groove corrosion, avoid welding defects like partial welding and lack of weld, which multiplies increase product life and reliability for more benefit to customers with superior cost savings.

Coiled Tubing

(Carbon Steel, CRA, Titanium Alloy)

Coiled tubing is a jointless tubing formed by welding several sections of flexible tubing with a length of more than 100 meters through butt welding or inclined welding. The length of coiled tubing is generally up to several hundred meters to several kilometers. It can be wound on a reel and used for specific downhole operations such as workover, drilling, perforation, stimulation, well completion, and logging. For applications in acidic environments, our company has developed high-chromium corrosion-resistant alloy coiled tubing and titanium alloy coiled tubing.

Encapsulated Cable (PDC/TEC, Flat Pack)

Encapsulated cable is special equipment used to deal with the harsh environment in the development and production process of oil and gas reservoirs. It is a product that uses metal materials such as stainless steel and nickel-based alloy steel to protect cables and other components from downhole pressure and corrosion environmental factors and uses polymer encapsulated materials to provide additional mechanical protection. It mainly includes PDC/TEC (Permanent Downhole Cable/Tubing Encapsulated Cable) and Flat Pack.